Industrial equipment releasing harmful emissions into the air are largely dependent on the use of electronic precipitators to control the emission rates since the specific heavy metals are highly stringent. Also known as electrostatic cleansers for eliminating impurities, either air or gas, solid, liquid, smokestack and other fuel, this precipitator functions effectively by applying energy to the collected particulate matter without impeding the gas flow out of the equipment. Hence, they are beneficial devices for air pollution control. You can consult a professional company for ESP internal supply.

Initially, the product’s design was for recovering valuable industrial process materials, while now it is efficient in removing harmful industrial particulate matter from waste gas and power generating stations. If the harmful matter is allowed to release into the atmosphere, it will reduce visibility in the air, contribute to climate change, consequently causing severe health issues in individuals like lung damage, heart diseases, bronchitis etc. These electrostatic precipitators can capture fine particles that are smaller than 2.5 microns and are highly dangerous when released into the atmosphere.

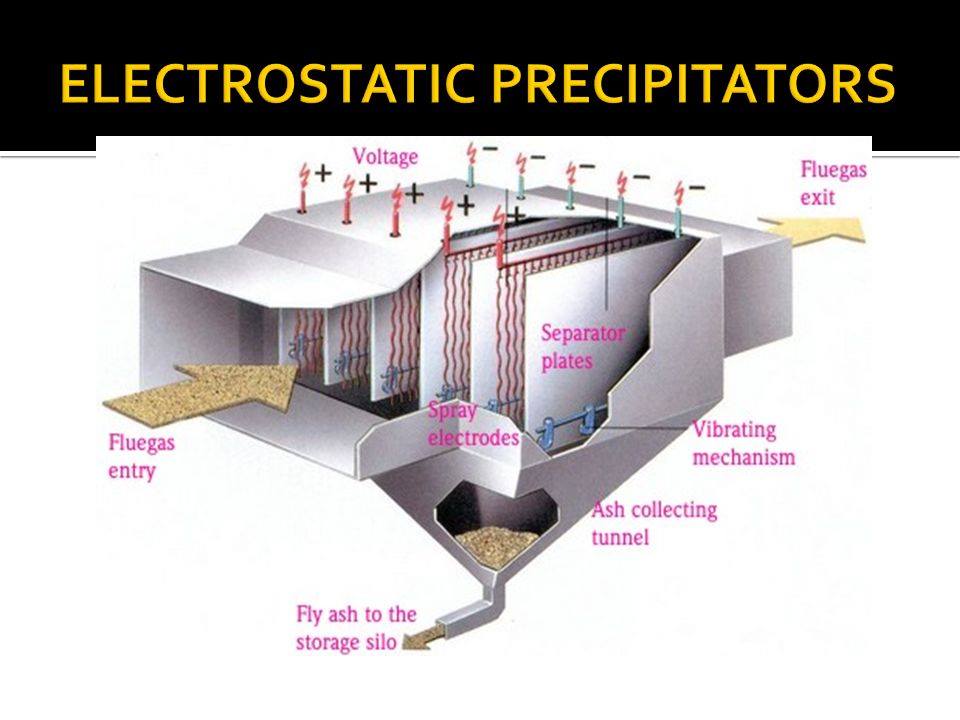

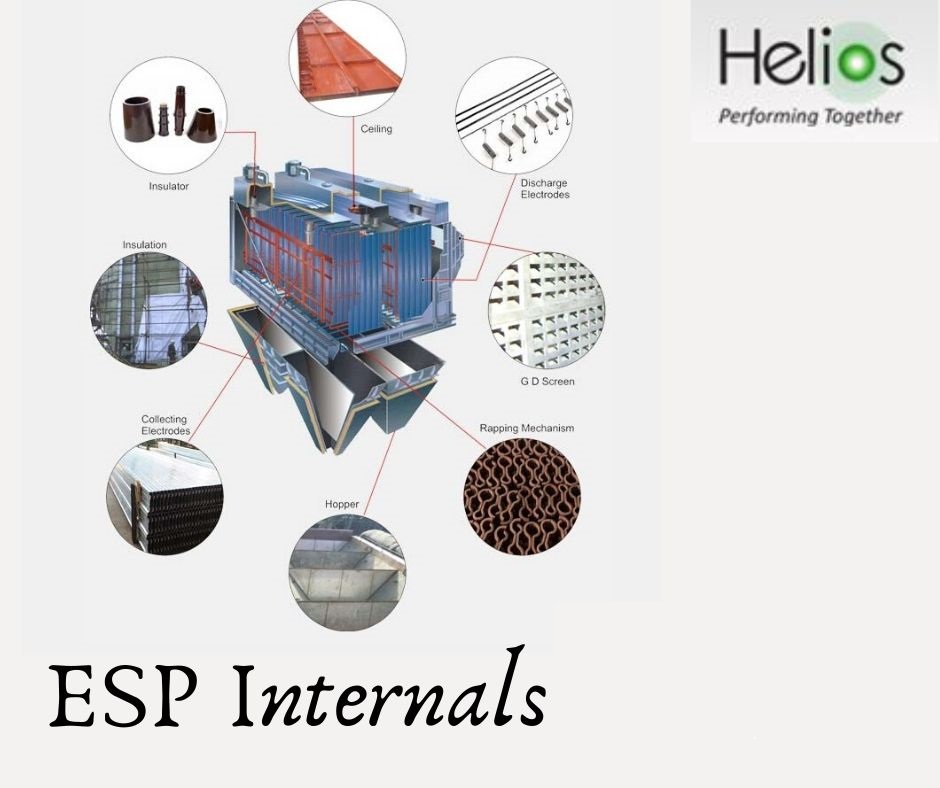

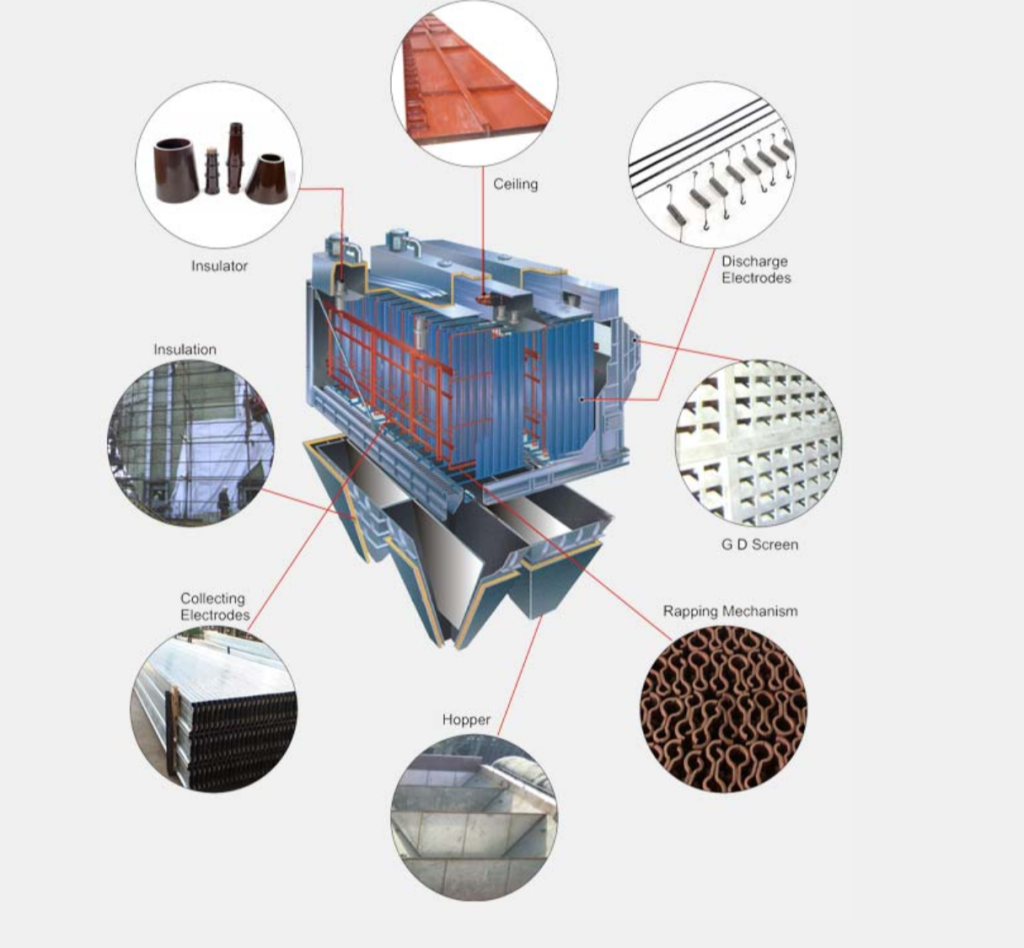

Design and Procedure

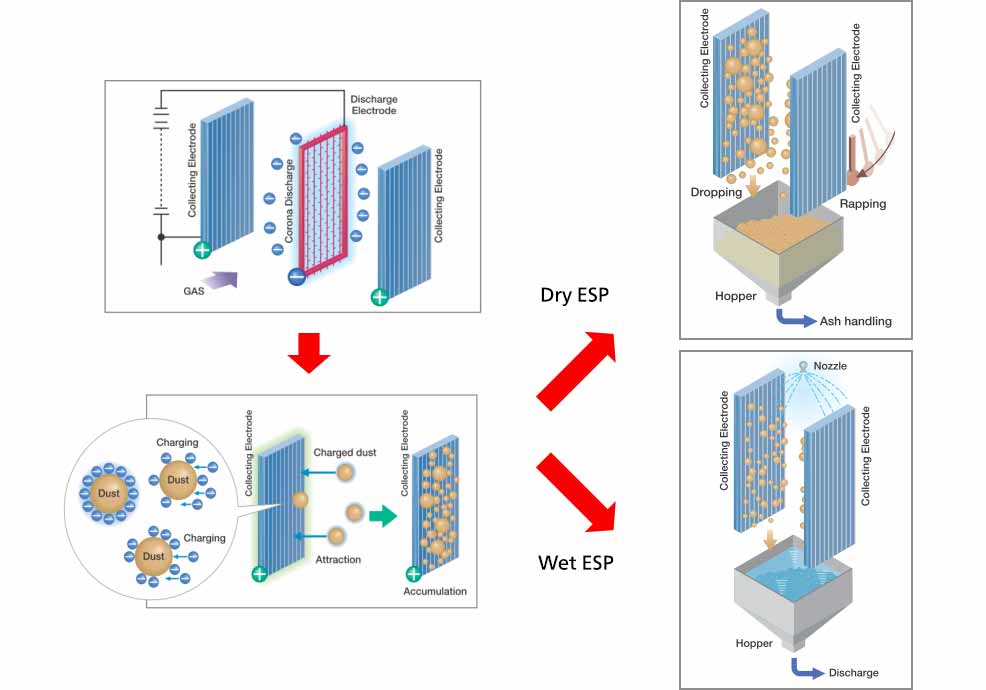

The electronic precipitators function by charging the particles in the gas stream electrostatically. The particles which are charged gets attracted to the plate and other kinds of collection devices. The treated air now passes through the precipitator, through a stack to the atmosphere. After enough particles accumulate on the collection device, the collectors shake it off via mechanical rappers. Be it dry or wet, these particulates now fall into the hopper at the bottom of the unit. The conveyor system transports it away for safe disposal. The ESPs also have denitrification units that remove nitrogen oxide and scrubbers removing Sulphur dioxide.

Advantages of ESP

- It has high durability and strength

- It effectively collects both dry and wet impurities

- The operating cost is extremely low

- The collecting capability of the device is high for smaller particles

- It is designed to handle a large volume of gas along with heavy dust loads at low temperature

Different Types of ESP

Plate Precipitator

This is the most basic type of precipitator consisting of stacks of vertically arranged flattened metal plates placed at distances of 1 cm and 18 cm and rows of thin vertical wires. The air stream passes horizontally through the vertical plates and after that through the stack of positioned plates. A negative voltage passes through the wire and plate to ionise the particles together. Now they are diverted toward the grounded plates making use of electrostatic force. The particles get collected on the collection plate and finally removed from the air stream.

Dry Electrostatic Precipitator

The precipitator collects pollutants like ash or cement in their dry state. The ionized particles flow through electrodes and a hopper, after which the particles are extracted. Now the collection of the dust particles from the air stream happens after hammering the electrodes.

Wet Electrostatic Precipitator

The precipitator removes resin, tar, paint, oil, which are wet in nature. The collectors are continuously sprayed with water which enables the collection of ionized particles from the sludge. This is how they are most efficient and effective than the dry ESPs.

Tubular Precipitator

This is a single-stage unit that consists of tubes that have high voltage electrodes. The arrangement is in a manner that it is parallel to each other in a way that they run on their own axis. The tubes’ arrangement is either circular, hexagonal honeycomb or square with gas flowing upwards or downwards. The gas passes through every tube to remove fine particles.

Know about the importance of ESP in reducing air pollution : https://www.linkedin.com/pulse/how-reduce-pollution-thermal-power-plant-nikunj-agarwal/